Cleanrooms form the backbone of pioneering advancements that drive progress in diverse fields. They enable critical applications ranging from semiconductor manufacturing and precision optics to biopharmaceutical production and advanced materials testing, enhancing our grasp of science and fuelling innovation.

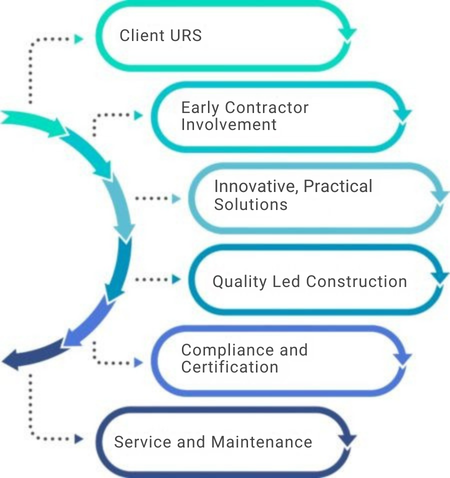

The expert construction, assembly, and deployment of cleanrooms play a pivotal role in realising our clients’ forward-thinking objectives. These spaces demand operational safety alongside adaptability to match the rapid shifts in scientific and industrial demands.

Through the fusion of decades of experience, and cleanroom systems, with industry leading QA systems, we have delivered compliant, operational cleanrooms first time – every time.

Our track record of delivering leading-edge installations spanning: aseptic filling cleanrooms for sterile pharmaceuticals, semiconductor cleanrooms for microelectronics biotech and Medical device cleanrooms including production facilities operating 24/7.

With our experience as a Specialist Contractor for building and maintaining facilities across all sectors, our groups expertise deliveries practical tailored solutions each of our project requirements.

As a recognised leader in cleanroom construction, our team has been involved in building over 100,000 square meters of cleanroom space for Multinational Pharmaceutical companies, hospitals, Institutes, Universities and government clients.

Our expertise spans Class 1 through 100,000 (ISO Class 3 to 8). We excel in implementing stringent environmental control requirements — cleanliness, vibration, temperature, humidity, electromagnetic interference, and airborne contamination — while ensuring flexibility for expansion, equipment, and infrastructure additions.